Nguyen Quang Minh Co., Ltd

Since its establishment in 1999, Quang Minh Candle has successfully built a good reputation for premium quality in Vietnam market. Since 2002, the company has exported its products to many countries including the United States, European nations, Japan, Australia, etc. Since its very first days, Quang Minh Candle is proud of being the pioneer in creating inspiration for the candle users and being a leading company in the market. During nearly 20 years of development, Quang Minh Candle has constantly improved its product quality. As our main goal is customer satisfaction, we are always committed to health and safety standards and continually striving for international quality by using materials imported from Malaysia, China, Germany, France, etc. and advanced manufacturing technology.

Our products are not only proof of completion in quality, aesthetics, and feng shui but also convey lots of spiritual meanings. Therefore, we believe each of our products is an amazing artwork brought to life.

Nguyen Quang Minh currently owns 2 factories, 1 warehouse with a total area of more than 6,000 square meters with the participation of more than 150 workers and modern equipment, machinery, we are confident to be one of leading candle suppliers in Vietnam. With 8 large-capacity production lines in operation, Nguyen Quang Minh is capable of reaching a capacity of 20 containers 40-feet per month in average, we are gradually developing to become a leading trusted supplier and globally well-known brand.

Factory 1

Address: Group 10, Binh Ky, Hoa Quy Ward, Ngu Hanh Son District, Da Nang City, VN

Factory 2

Address: Group 15, Khai Tay, Hoa Quy Ward, Ngu Hanh Son District, Da Nang City, VN

.jpg)

Production process

Materials

Raw Materials will be thoroughly tested for quantity as well as quality according to an established process. All Unsatisfactory elements will be removed or handled before being used for ensuring product Quality

Production

Base on Production Order from Sales team, Technical Department, Production Department, QC/QA Department will work together as procedure for a mass production. There are always supervision and coordination between the departments throughout the manufacturing process

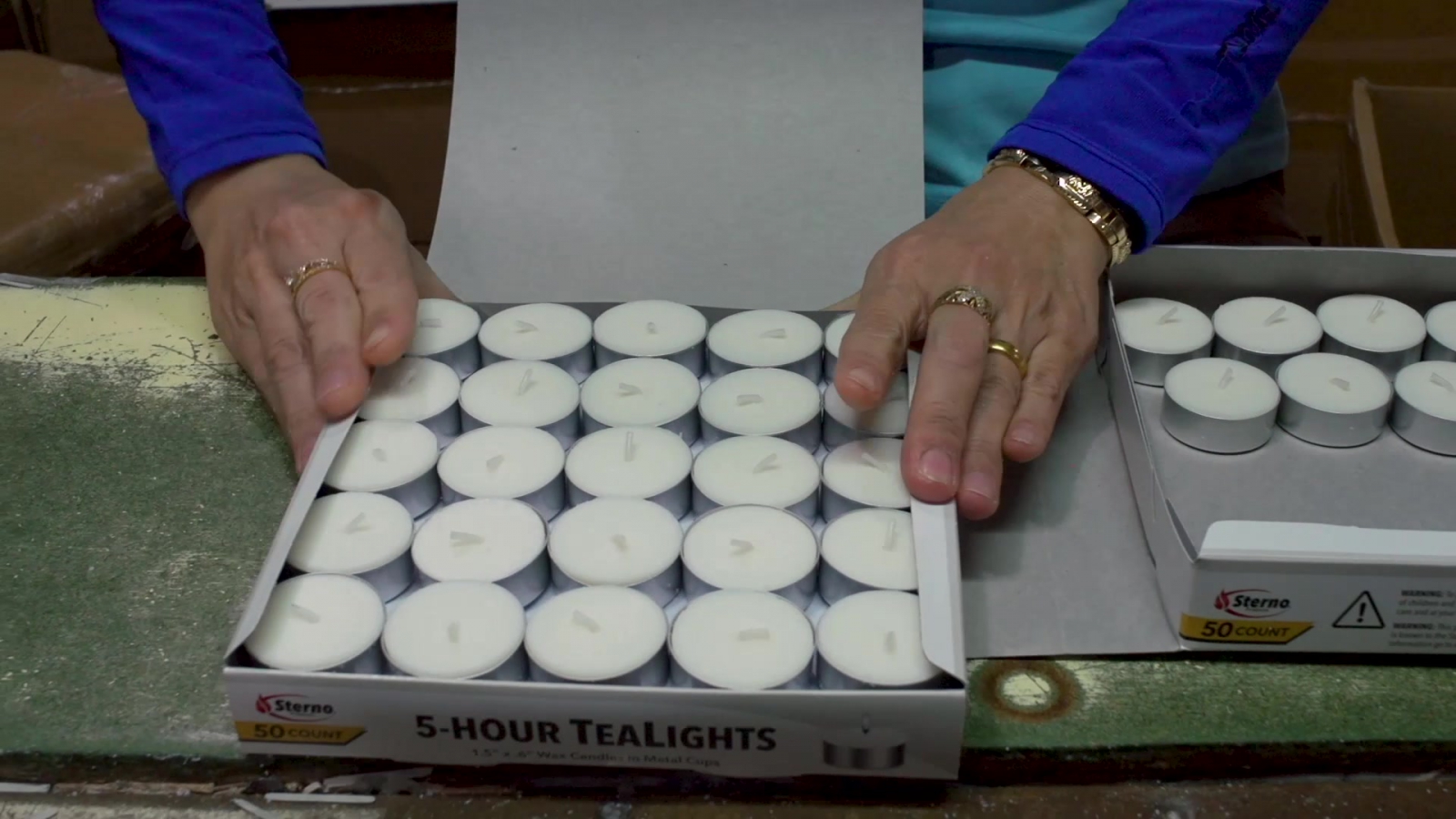

Packaging

Finished goods will be packed according to a standard or customer requirements .

This is the last stage of production process. Goods will be checked again before being packed

Quality Control

Testing final products will be performed by QC Department. Only products passed by QC are eligible for shipment.

All reports are recorded as a format for reference.

.png)

Storage

After all of the above stages, the goods are stored at the warehouse, ready to ship.

Team work

.png)

PRODUCTION TEAM

This department directly coordinates the production process, they always have to plan and monitor the production to ensure the correct work progress.

They are: Production Manager, Production Management Assistant, Leader of Lines.

TECHNICIAL TEAM

Technical department issue technical datasheet base on order & verify sample and combined to other departments for smooth work.

In addition, this department is also responsible for product quality. They provide a better formula for present products as well as research for new products.

SALES TEAM

Solve problems related to Customers. Sales Team help us more understand Customer Insight.

They are: Sales Directors, Sales Manager, Salesman

QC/QA TEAM

This department control at most of processes from Imported Materials to Final Products so all problems related to products are detected and handled timely.

They collects, completes all reports and keep the records for reference.

They are 6 QC in line and 1 QA

Activity

Besides working, Our company regularly organizes many outside activities to encourage employee’s spirit. We would like not only response customer satisfaction but also bring comfort to all of our staffs.

We always facilitate the best condition to all members for the best development.

For us, Nguyen Quang Minh is a group and the growth of a group comes from strength of each member.